一、WMS/WCS Intelligent Warehouse Control System

1、WMS Intelligent Warehouse Control System

WMS System Overview: The Warehouse Management Information System (WMS) is an integrated management system that encompasses inbound and outbound operations, warehouse and inventory reallocation, virtual warehouse management, and more. It combines features like batch management, material mapping, inventory checks, quality control, and real-time inventory management.

Effective Logistics and Cost Control: The system offers comprehensive control and tracking of warehouse logistics and cost management processes, ensuring robust storage information management for enterprises.

System Functionality: Capable of independent inventory operations and compatible with other systems through interfaces, providing a more holistic view of business processes and financial management.

Inventory Management: Features include batch inventory management, early warning systems, visual inventory tracking, transfer management, stocktaking, and replenishment.

Inbound and Outbound Management: This includes document management, shelving strategies, allocation planning, wave-based dispatching, task assignments, and packing verification.

Location Management: Covers management of aisles, storage locations, ports, key points, and containers.

System Administration: Encompasses user and role management, operation logs, permission settings, and system interfacing.

2、WCS Intelligent Warehouse Control System

Overview of WCS System: The Warehouse Control System (WCS) functions as a dispatch system. It serves as an intermediary between automated storage management systems and PLC control systems, establishing connections through internal protocols. This system orchestrates the management and monitoring of automated warehouses, controlling various logistics equipment. The communication process enables interaction between management/monitoring systems and various logistics devices. The logistics process allocates storage locations for goods based on transportation and storage requests from lower-level machinery, generating task instructions accordingly. The dispatch process prioritizes and queues tasks based on dispatch rules and priority levels.

Task Management: Incorporates task segmentation, prioritization, route management, node actions, and manual intervention.

Equipment Management: Covers equipment master data, status management, anomaly handling, and maintenance.

Dispatch Center: Encompasses task distribution, route planning, traffic management, execution of commands, collaborative avoidance strategies, and dispatch policies.

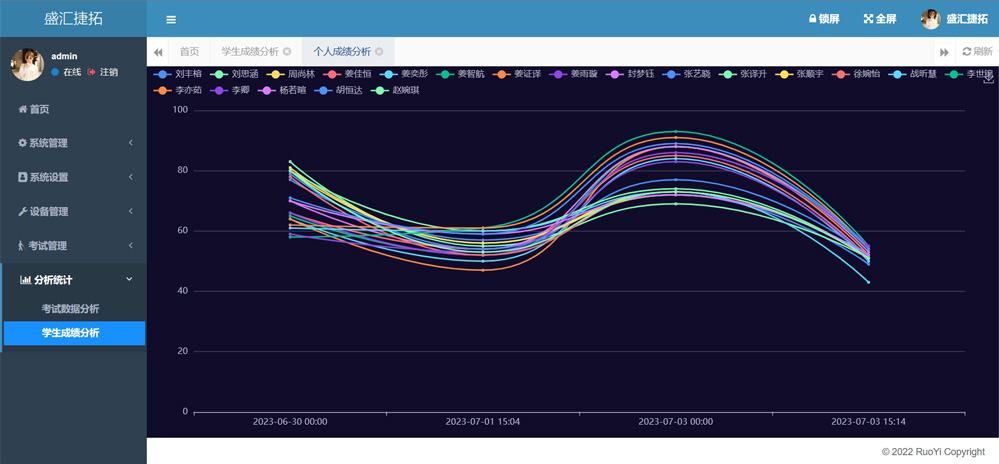

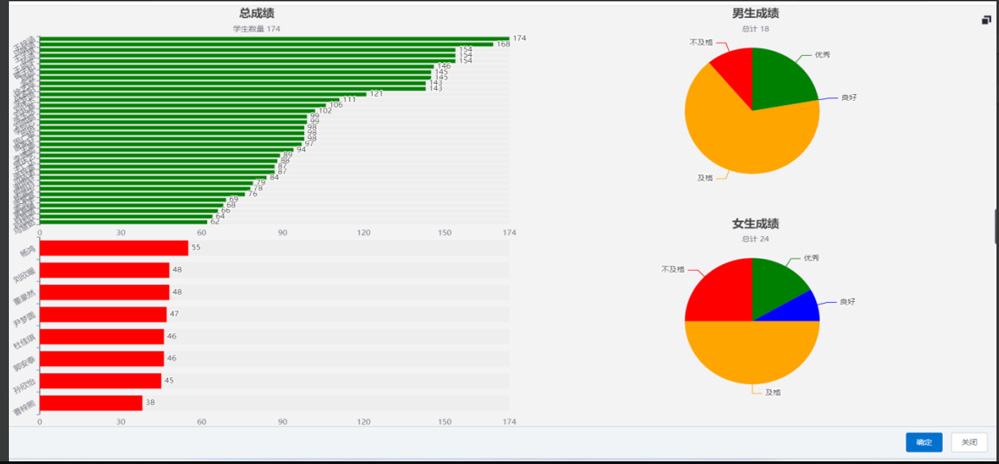

Visual Monitoring: Features equipment monitoring, statistical visualizations, and alarm notifications.

Interface Management: Handles equipment interfaces, connections with higher-level systems, and logs of interface activities.

二、Smart Campus System

Zhi Sheng Da Jump Rope System: Employs Bluetooth 5.1 technology for multi-link connectivity, supporting 60 or more ropes simultaneously, with a quick connection setup time of 15 seconds. This system ensures stable two-way communication and can operate at a range of up to 100 meters. Designed to meet physical testing standards, it allows interactive sessions with multiple jump ropes and can be customized to different regional requirements with modes like count jump, timed jump, and free jump. After testing, the AI analyzes and compares various data sets. It is integrated with a proprietary cloud database, which records every jump session by linking each rope to individual student profiles.

Innovative Physical Education: Aids in the high-quality development of students' physical activities and school sports programs. The company's aim is to promote healthy growth in youths and enhance the quality of school sports programs by providing intelligent, real-time, and convenient products. These products build upon traditional sports equipment by integrating smart modules, enhancing aesthetics without compromising the user experience.