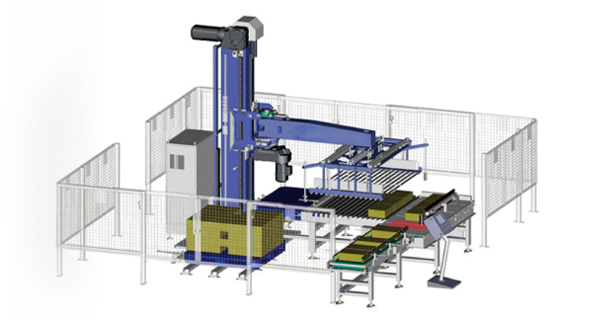

The column robot is widely utilized in industries that handle bagged, barreled, and boxed packaging, for palletizing and transporting tasks. This equipment utilizes a robotic control system to achieve direct line interpolation from point to point, resulting in smooth and fluid movement. The teaching pendant facilitates the control of the industrial robot’s movements through key controls and display functions, enabling operators to easily perform teaching control of the manipulator's movements. Pallet patterns are pre-stored and can be flexibly operated; during work, the robot completes the stacking of bagged products according to the preset grouping method and layer count.

1.High working efficiency: Capable of 400-500 picks per hour.

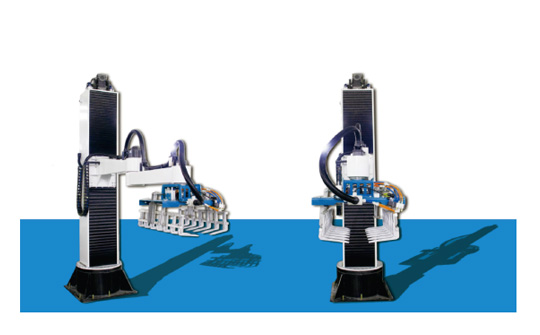

2.High operational precision: Large working range with a small footprint, and flexible actions.

3.Customizable pallet patterns and stacking layers: Can be set as required, ensuring neat and stable stacks, facilitating storage and transportation.

Workflow:

The column robot palletizer operates by conveying the packaged materials to a designated palletizing area. The robot, coordinating its axes, moves the gripper directly above the material. When the positioning signal is emitted, the gripper, controlled by a servo motor, descends (i.e., along the Z-axis) to grip the material. After gripping, the Z-axis servo motor reverses, raising the gripper to a safe height before transporting the material to the palletizing position according to the pre-programmed sequence. The Z-axis lowers to place the material at the designated spot, releases it, and repeats the process until the pallet is fully stacked. A buzzer alerts when palletizing is complete. The completed pallet is then removed, a new pallet is placed, and the cycle is repeated.

Equipment Advantages:

The column robot palletizer's joints use RV reducers and are made from high-quality materials, ensuring a simple, rational structure that's easy to operate and maintain. The equipment operates smoothly and reliably, with flexible actions, high precision, and a large operational range. It offers low overall application costs due to fewer main components, resulting in lower maintenance costs and power consumption, and a low failure rate. Pallet patterns and stacking layers can be set arbitrarily, resulting in neat, stable stacks that are convenient for storage and transport.