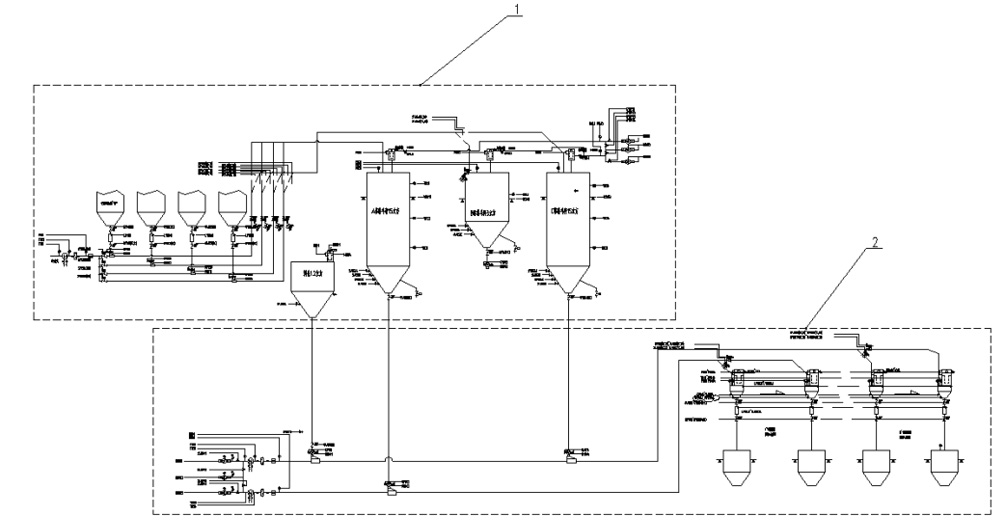

The system is fitted with a dryer and filter at the start of the conveying pipeline. Under the action of a negative pressure fan, and after passing through the dryer and filter, the material falling from the upper hopper is transported via the conveying pipeline to the ABC storage silo for temporary storage. The material in the temporary storage silo is released into the positive pressure conveying pipeline through a rotary valve. It is then conveyed to a smaller silo by the positive pressure fan. The bottom of this smaller silo is connected to a container specified by the client via a pneumatic butterfly valve. This valve is programmed for automated control, enabling automatic opening and closing. Dust collectors mounted on top of each silo further purify the discharged gases. This entire system automates the transfer of materials to client-designated locations, significantly conserving manpower and resources.

The pneumatic conveying system's main function is to transport powder to the furnace using both negative and positive pressure techniques. As illustrated in the system node diagram above, it is divided into two key components based on functionality:

Negative Pressure Pipeline Pneumatic Conveying System

Positive Pressure Pipeline Pneumatic Conveying System