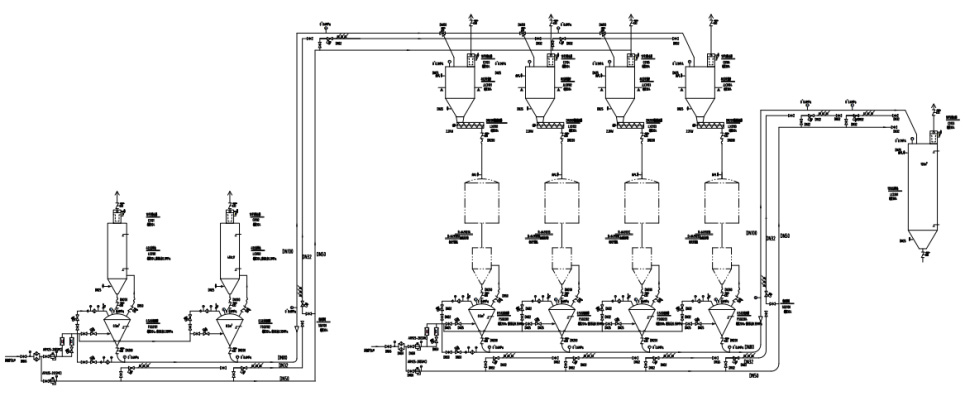

The conveying mechanism comprises two separate sections of positive pressure pneumatic pipelines. The initial segment facilitates the process of material addition or automated unpacking into a designated feed bin. Subsequently, the materials stored in this bin are transported to an intermediary weighing scale through a positive pressure pneumatic system. This system boasts a conveyance capacity of 2.5 tons per hour. The intermediary scale then transfers the materials to the reactor via a screw conveyor, operating at a feed rate of 1.2 tons per hour and maintaining a precision level of 0.5%. The medium employed for conveying is compressed air, utilized within a dense-phase open loop system. The system is engineered for a horizontal reach of up to 200 meters and a vertical ascent of 30 meters.

The second segment of the positive pressure conveying system is responsible for moving solid materials from the drying apparatus to a storage silo with a capacity of 100 cubic meters. This segment, mirroring the operational principles of the first, also employs compressed air in a dense-phase open loop configuration. Its preliminary design accommodates a horizontal transit of 140 meters and a vertical lift of 30 meters, with an impressive conveying capacity of 5 tons per hour.